High Technology

Technology

Push the limits of stencil printing!

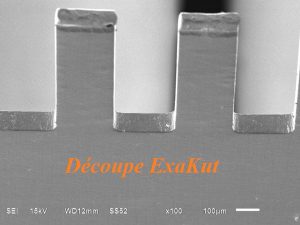

After two years research and development, the DB Products team has developed an exclusive manufacturing process allowing an optimal stencil printing for the most critical components.

High density cards and mixed components are no longer an obstacle.

We were faced with three challenges:

- Improve the solder paste release ratio (users notice a 40% improvement).

- Increase printing reliability and repeatability.

- Reduce underside cleaning.

Platinum stencils

Platinum stencils, manufactured by our Partner DEK Singapore, allow high precision apertures with almost no dimensional limits,

- 45um openings in 50um steps

- Round openings of 7um, thickness 38um

- Précision : +/- 3µm

They are the printing solution for semiconductor applications: Wafer, direct chip attach, BGA …

Ball Placement Application

The ball placement stencil is used with a DEK patented spray head and a flux or solder paste removal stencil. With this stencil you will deposit balls. (200μm to a few millimeters diameter)

In a few seconds, you may deposit 100% of your matrix balls with an accuracy of a few microns.

Learn more about Ball placement

LSE surface treatment

The LSE surface treatment developed by the DB Products team is a special permanent coating that considerably reduces the frequency of cleaning cycles for printing machines (productivity benefit and consumables cost reduction), also facilitating the cleaning of stencils after production. This treatment, available as an option on ordering your stencil, is always applied on Exakut stencils